Enabling Aftermarket Service for complex industries

Plan. Price. Service.

Syncron’s Connected Service Experience (CSX) Platform revolutionizes aftermarket operations by integrating sales and service processes with AI/ML-powered solutions, predictive analytics, and configurable automation. Propel your business into the future, capitalizing on the new service economy, and turn insights into sustainable growth. With Syncron, set the pace in service transformation.

Trusted by the world’s leading manufacturers

Empowering today and tomorrow

At Syncron we can help you embrace servitization and embed service into your equipment lifecycles to turn complex challenges into competitive differentiators. In doing so, we are able to drive better aftermarket business growth, evolve experiences and enable intelligent service.

We’ll empower your business to gain increased predictability with data-driven intelligence to support key decision makers. Additionally, we’ll accelerate your business performance, speed to market and aftermarket service quality by eliminating unplanned downtime through predictive capabilities to support greater resilience and continuity.

With Syncron’s CSX Platform you can:

Drive revenue growth and improve profitability

Reduce operational costs and mitigate risk

Support greater customer value, loyalty and industry reputation

Meet sustainability

and net zero targets

Unlock the value of AI/ML

in the aftermarket

AI/ML-based technologies reduce cost, generate revenue, and support Original Equipment Manufacturers (OEMs) environmental goals. Precision inventory management, parts price optimization and enhanced collaboration between OEMs, aftermarket partners and technology companies are all important parts of the industry shift towards customer experience and sustainability powered by advances in AI technology.

Syncron CSX Cloud

We can help solve your service lifecycle business challenges

Streamline parts planning and optimization

Optimize service parts inventory ensuring parts are at the right place at the right time to enhance service experiences with more immediate availability.

Supply Chain OverviewDevelop intelligent optimized aftermarket pricing strategies

Accelerate speed to market, price parts more competitively, and unlock revenue potential, increase margins, reduce risk and exceed customer expectations.

Go To Market OverviewDigitize and connect service management operations

Connect and simplify service delivery, streamline warranty processes, and increase uptime to enable increased operational resilience and continuity making the right information required during repair time available.

Service Fulfillment OverviewWhy choose Syncron?

Leading brands trust our solutions and team. We’re specialists in aftermarket sales and service, with deep experience that mitigates risks as you embark on your service transformation journey. Our insights into the intricacies of this domain ensure best-in-class solutions for your strategic needs. Rely on our advanced AI/ML based integrated solutions on our cloud-based platform, underpinned by our unwavering commitment to customer excellence and innovation, to seamlessly guide and future-proof your business operations.

Our latest blogs

See all

A Year-End Review of Aftermarket Trends and a 2024 Outlook

Recently, Dr. Friedrich “Fritz” Neumeyer, CEO of Syncron, engaged in a thought-provoking conversation with industry… from A Year-End Review of Aftermarket Trends and a 2024 Outlook

Contract Price Optimization: A New Category in Aftermarket Price Optimization

The changing dynamics of the aftermarket In today’s business world, evolution is constant. Industries are… from Contract Price Optimization: A New Category in Aftermarket Price Optimization

Enhanced Warranty Management Systems for Manufacturers

A Warranty Lifecycle Management solution streamlines warranty processes, reduces costs, and boosts customer satisfaction. Yet,… from Enhanced Warranty Management Systems for Manufacturers

Resources

See all

Build a Resilient Aftermarket Service Business

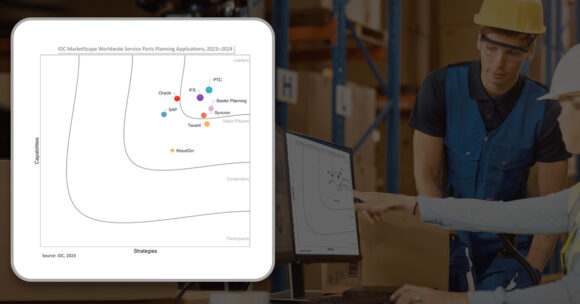

A Leader in the IDC MarketScape for Worldwide Service Parts Planning Applications 2023–2024

A leader in service parts planning Syncron has been named a Leader in the IDC… from A Leader in the IDC MarketScape for Worldwide Service Parts Planning Applications 2023–2024

Unlocking Business Success in Aftermarket Parts Planning: Strategic Roadmap

Understand the metrics that will move the needle With insights from SaaS solution experts and… from Unlocking Business Success in Aftermarket Parts Planning: Strategic Roadmap

Achieve breakthrough moments

Want to learn why the world’s leading manufacturers choose Syncron for aftermarket service management solutions? Simply complete the form and a member of our team will contact you within one business day.

Contact Us Discover CSX Platform