- Disruption

The Circular Economy

Circularity in Manufacturing

Manufacturers play a pivotal role in the wider societal shifts to replace the traditional linear take-make-dispose model with a closed-loop circle where resources are repaired, reused, and recycled.

- Defining Circular Economy.

- Circularity in manufacturing.

- Product life extension & reverse supply chain networks.

The vast majority of the world’s manufacturers have a wealth of opportunities to make more money and increase returns to shareholders by using fewer resources.

McKinsey

• More from less: Making resources more productive

What is the Circular Economy?

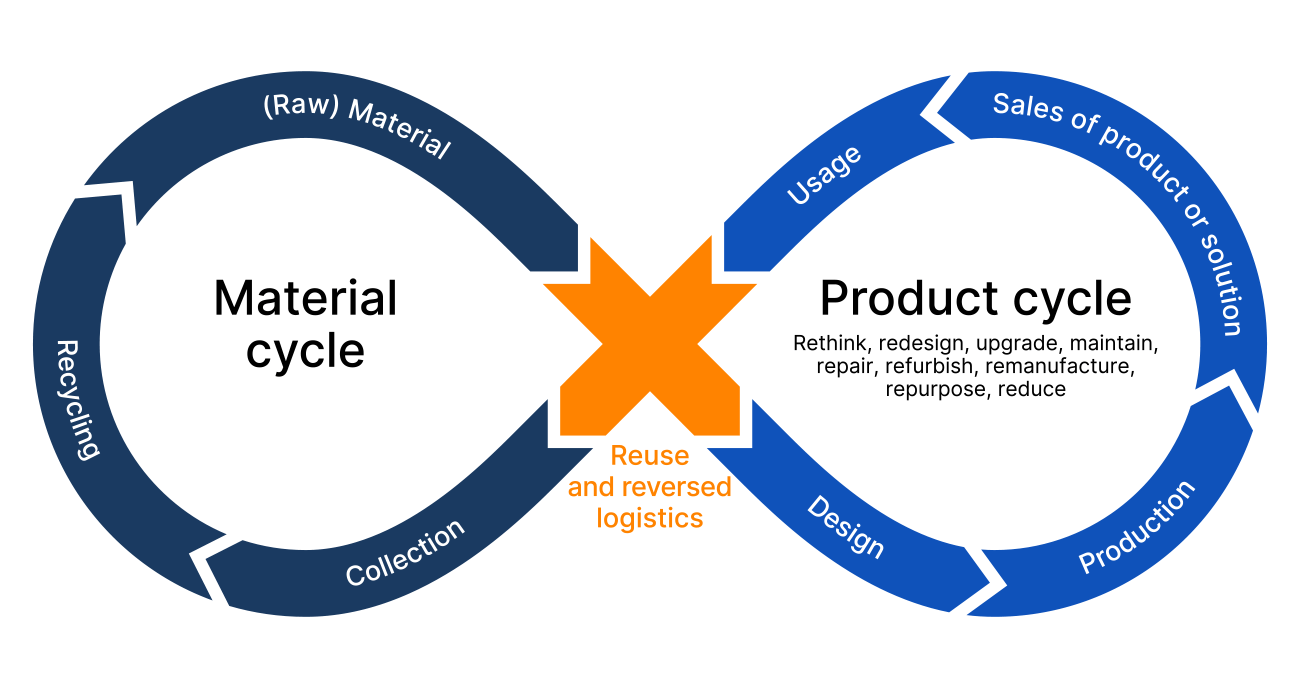

The circular economy is an economic model that aims to keep resources in use for as long as possible, reducing waste and optimizing resource use. Instead of the traditional take-make-dispose model, the circular economy creates a closed-loop system where resources are reused.

-

Reduce, reuse, repair.

-

Recapture, refurbish.

-

Remanufacture, recycle.

What does circular economy mean for manufacturers?

Circularity can lower sourcing risks and costs, improve efficiencies, and open new markets but also mean designing products for repair and disassembly. More importance is placed on field maintenance and reverse supply chains to close loops and extend product life depending on complexity and value of product.

-

Lower sourcing risks and costs.

-

Open new markets.

-

Reverse supply chains close loops.

How does Syncron help?

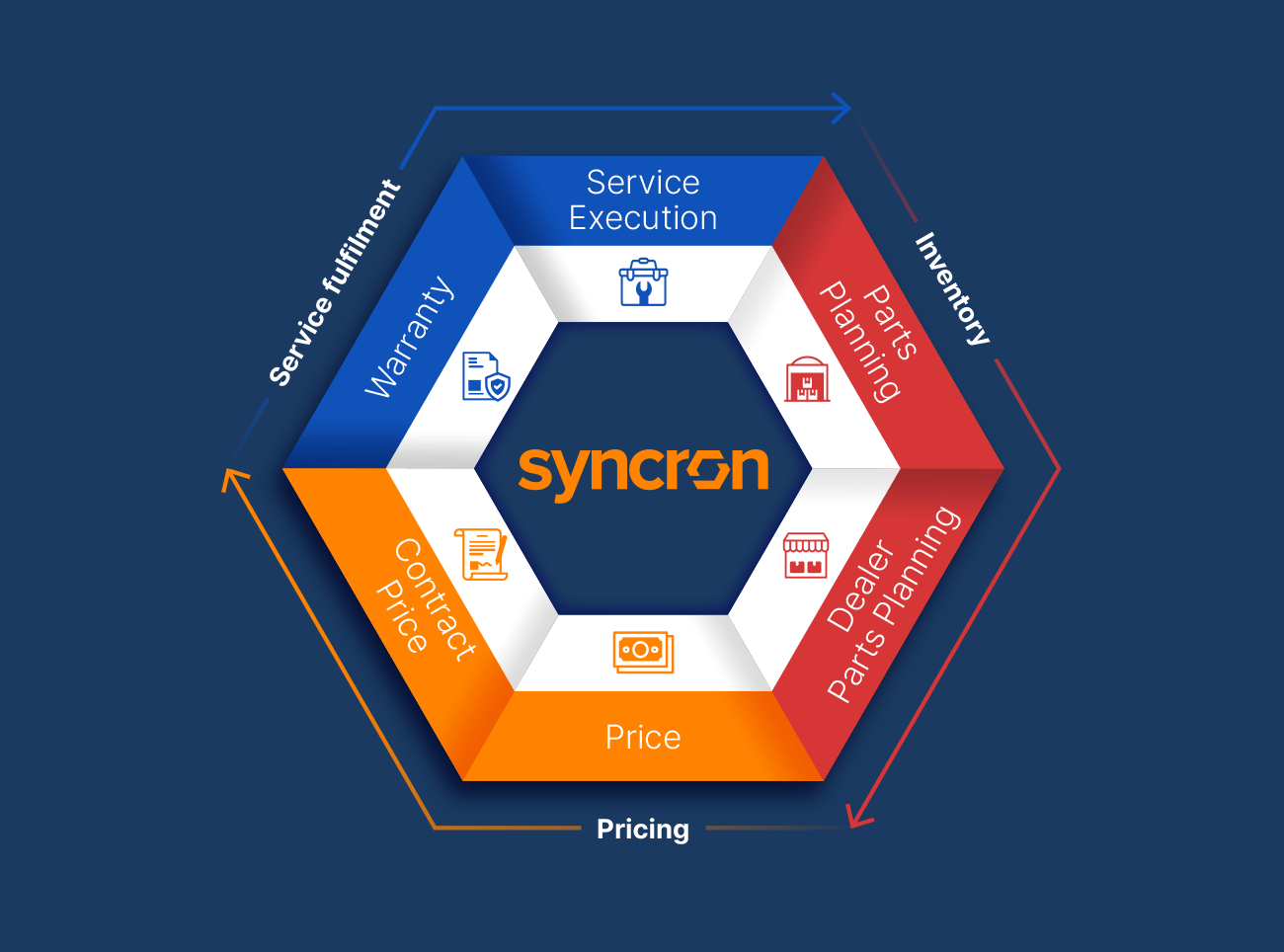

As manufacturing shifts towards a circular economy, close collaboration and consolidation of product information is needed across the value chain. Syncron data platform optimizes reverse supply chain networks and streamlines the end-to-end repair and maintenance process.

-

Comply with environmental regulations.

-

Extend product lifespan.

-

Streamline product returns.

Resources

6 Questions With… Rob Joseph

- Leadership

What Happens When Aftermarket Leaders Claim the Seat They’ve Already Earned

Rethinking the Role of Parts: Lessons from the Service Council™ Smarter Services™ IdeaShare

6 Questions With...Amit Rana

- Leadership

From Invisible to Indispensable: How to Build Influence as an Aftermarket Leader

- AI

- machine learning

Why Spare Parts Demand Forecasting Is a Different Game

- Leadership

The Metrics That Matter: How Aftermarket Leaders Can Reframe Performance

- Dealer Parts Planning

- Retail Inventory Management

Build vs. Buy: The Hidden Costs of Going It Alone

The Mid-Market Advantage: Why Agility Wins in the Service Economy

- Press Releases

Syncron Named a Major Player in the IDC MarketScape: Worldwide B2B Revenue and Profit Optimization Platforms 2025-2026 Vendor Assessment

6 Questions With… Mark Dabe

- Dealer Parts Planning

- Retail Inventory Management

Are You Ready for RIM? 5 Key Questions OEMs Should Ask

- Leadership

Why Running the Aftermarket Is a Smart Career Move

- Parts Planning

- Press Releases

Syncron Expands Global Value-Added Reseller Program with Tridant Partnership in Australia and New Zealand

Don’t Just Sell the Number. Sell the Truth.

- Dealer Parts Planning

- Retail Inventory Management

Retail Inventory Management: The Opportunity OEMs Can’t Afford to Miss

- Parts Planning

Aftermarket Winning Strategy: Straight From an NFL Playbook

- Agriculture