Make Profit Not Waste With Advanced Inventory Management

The only purpose-built AI-powered service parts planning software for equipment manufacturers and distributors from the IDC Worldwide Manufacturing Service Parts Management Applications Leader and aftermarket specialist.

- Reduce excess stock and avoid future obsolescence and scrappage.

- Carry the right stock, in the right place, at the right time to drive sales.

- Reduce emergency freight costs through optimized stock availability.

Trusted by the best

Aftermarket designed: Inventory management

Full network demand planning and optimized inventory management. Leverage inventory optimization across extensive supply chain networks. Supplier portal for clarity and control over data, fostering collaboration across the entire supply chain. Restock Inventory with virtual warehousing and returns management.

-

Multi-echelon inventory optimization.

-

Supplier portal.

-

Automate restocking planning.

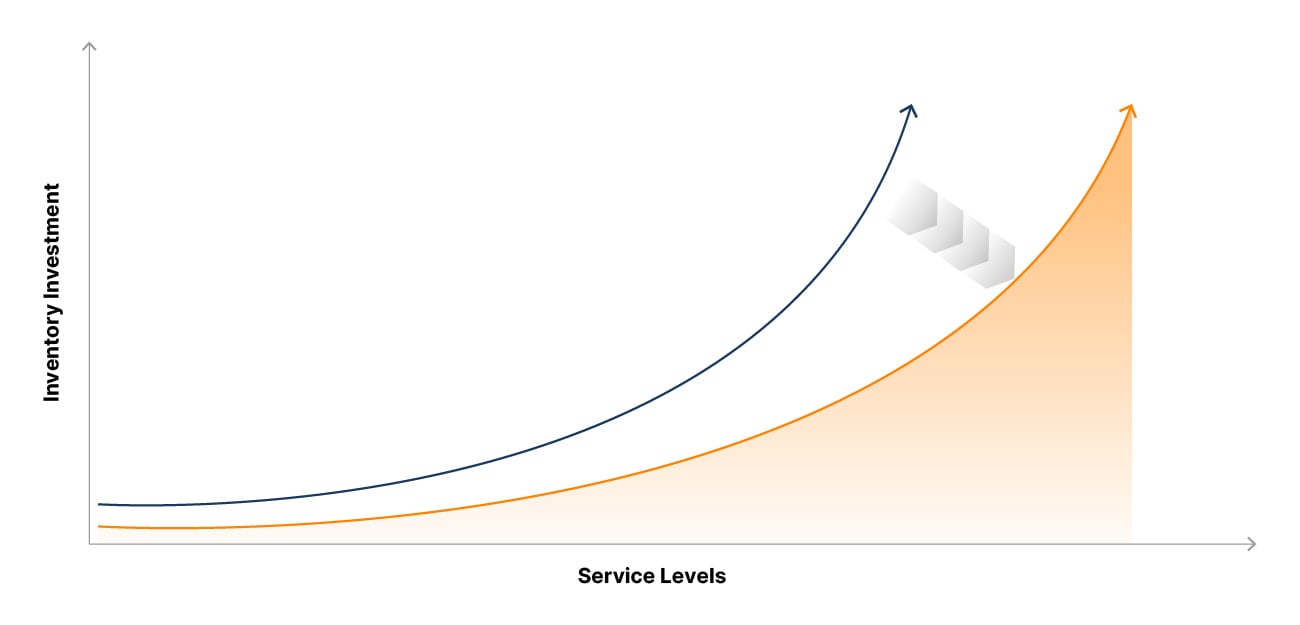

Shift the curve: Take a blended approach

Syncron Parts Planning allows you to:

-

Deliver current service levels at a lower level of investment.

-

Improve service levels at the lowest possible cost.

-

Reduce non-contributing assets.

Service levels vs. investment

Raising or lowering service levels or parts availability has a corresponding effect on the inventory investment required to maintain them.

Adding or reducing inventory investment has the same effect to service levels – effects are heightened at both extremities.

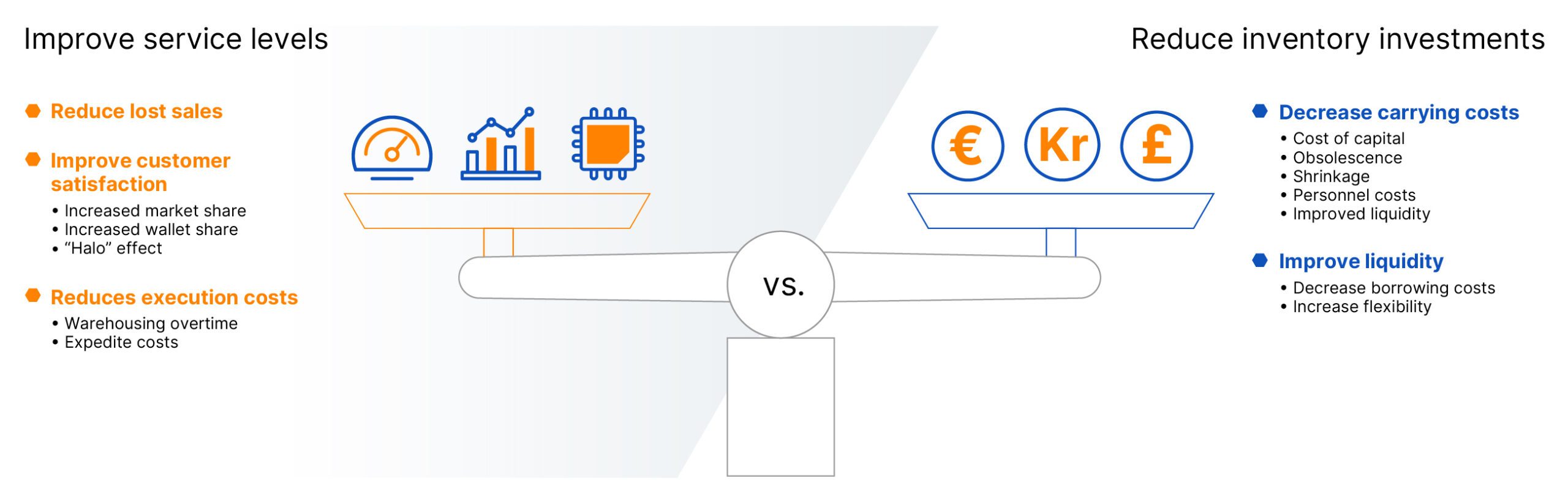

Decrease carrying costs & improve liquidity

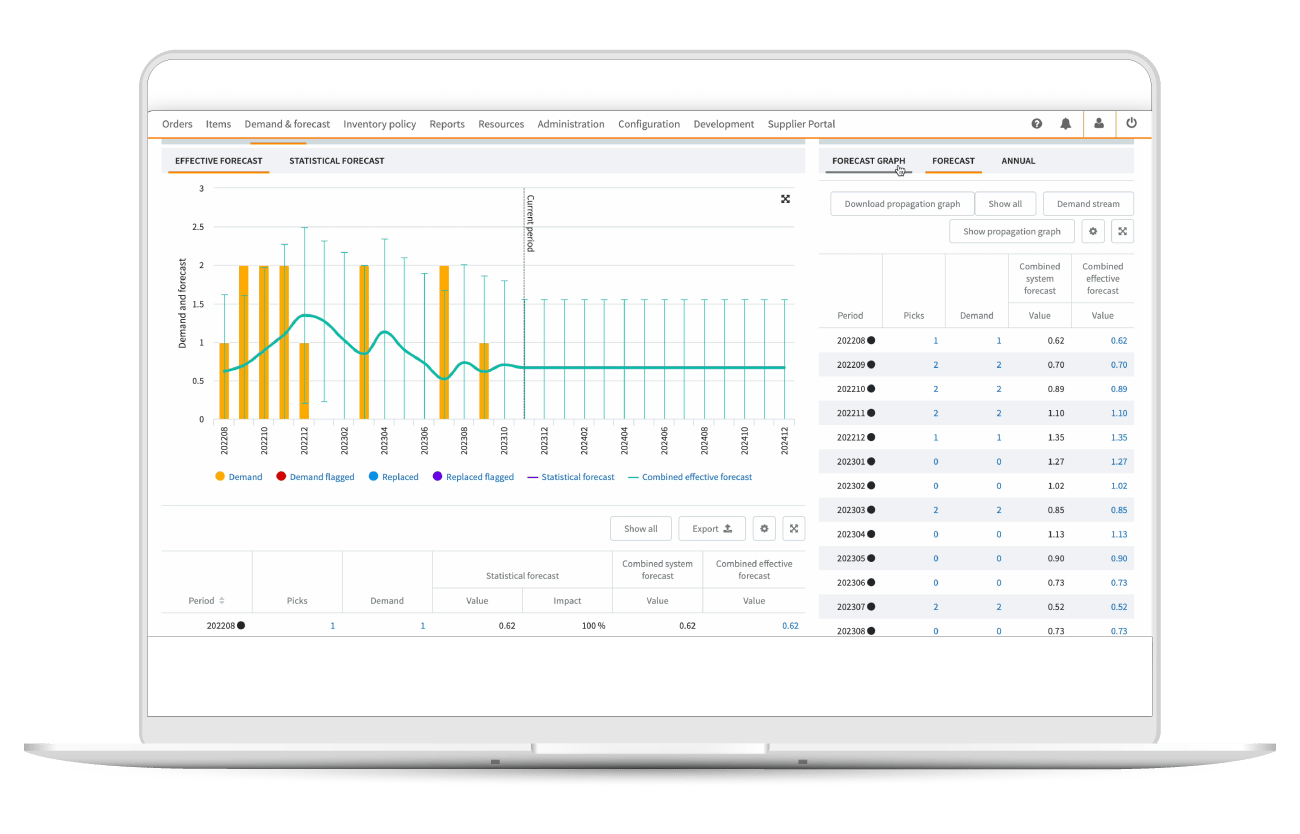

Demand driven: Intelligence led

Probabilistic AI models optimized to accurately predict demand patterns across millions of service part-location combinations. Dynamically classify items into 9 pre-defined demand types based on item movement.

-

Statistical Install Base & Causal Forecasting.

-

Full supersession support.

-

Aggregate demand across BOM.

Seasonality & outlier detection

Identify seasonality at the individual item level or in a group of items. Automatically identify and calculate seasonality factors. Cluster items known to be seasonal.

-

Pinpoint outlier periods/transactions.

-

Calculate seasonality factors.

-

Cluster seasonal items.

Improve service levels & sales

Reduce freight costs & emissions

Connect service level and cost analysis with carbon emissions from logistics methods. Minimize stock holding, freight, and other costs associated with aftermarket supply chain while increasing service levels.

-

Lower aftermarket supply chain costs.

-

Reduce CO2 emissions.

-

Simulate CO2 emissions at scale.

Automate replenishment to mitigate lost sales

Execute established inventory replenishment for ordering parts stock and optimize availability.

-

Maximize order fill up.

-

Share order schedules and plans.

-

Reduce emergency orders and lower shipment costs.

Designed for complex networks

Proven: Return on investment (ROI)

Part availability, or service level, is the main driver of customer satisfaction in after-sales service. Syncron is IDC Worldwide Manufacturing Service Parts Management Applications Leader and aftermarket specialists.