サービスパーツ在庫計画に特化したソフトウェア Syncron Parts Planning

無駄を減らし

利益を最大化する、

高度な在庫管理

製造業に特化した、AI搭載のサービスパーツ在庫計画のソフトウェア。IDC*認定の世界的な製造業サービスパーツ管理のアプリケーションリーダーであり、アフターマーケットのスペシャリストであるシンクロンが提供します。

- 過剰在庫を削減し、将来起こり得る廃棄や陳腐化を防止します。

- 必要な在庫を適切な場所とタイミングで確保し、売上を促進します。

- 在庫を最適化することで緊急輸送費の削減につなげます。

*ITおよび通信分野に関する調査・分析、アドバイザリーサービス、イベントを提供するグローバル企業。

シンクロンは世界中の大手グローバル企業に信頼される、サービスパーツ在庫計画のソリューションブランドです。

アフターマーケットに

特化した設計で在庫管理

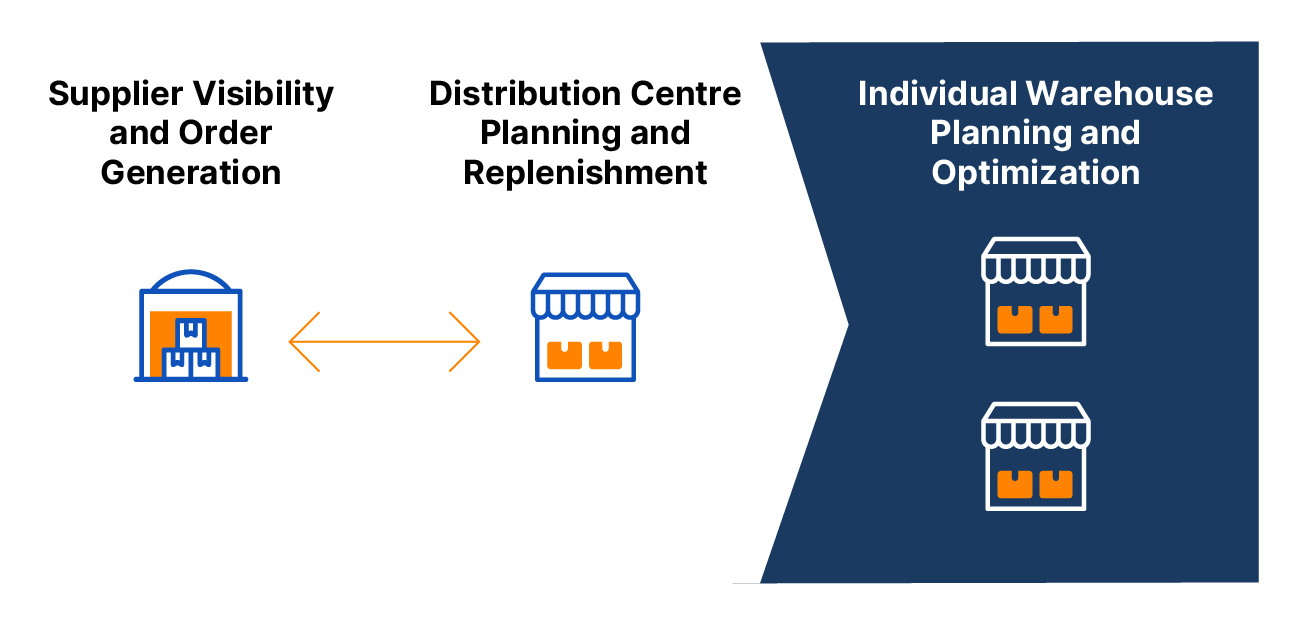

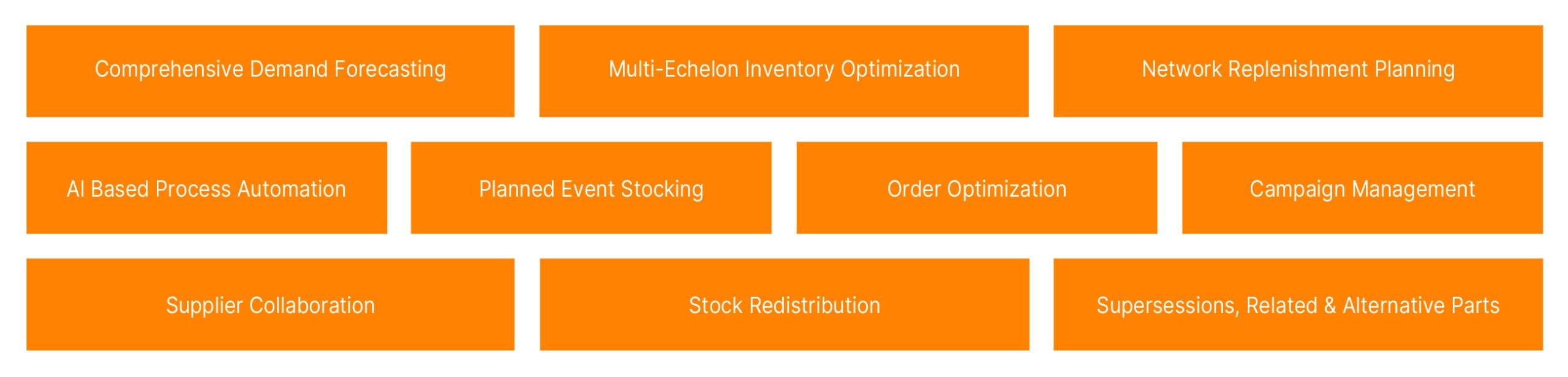

全ネットワークの需要計画と最適化された在庫管理を提供。広範なサプライチェーンネットワーク全体で在庫の最適化を実現。サプライヤーポータルにより、データの透明性とコントロールを強化し、サプライチェーン全体での協力を促進。バーチャル倉庫と返品の管理を活用した在庫の補充が可能です。

- マルチエシェロン在庫最適化

- サプライヤーポータル

- 再発注計画の自動化

多角的なアプローチで

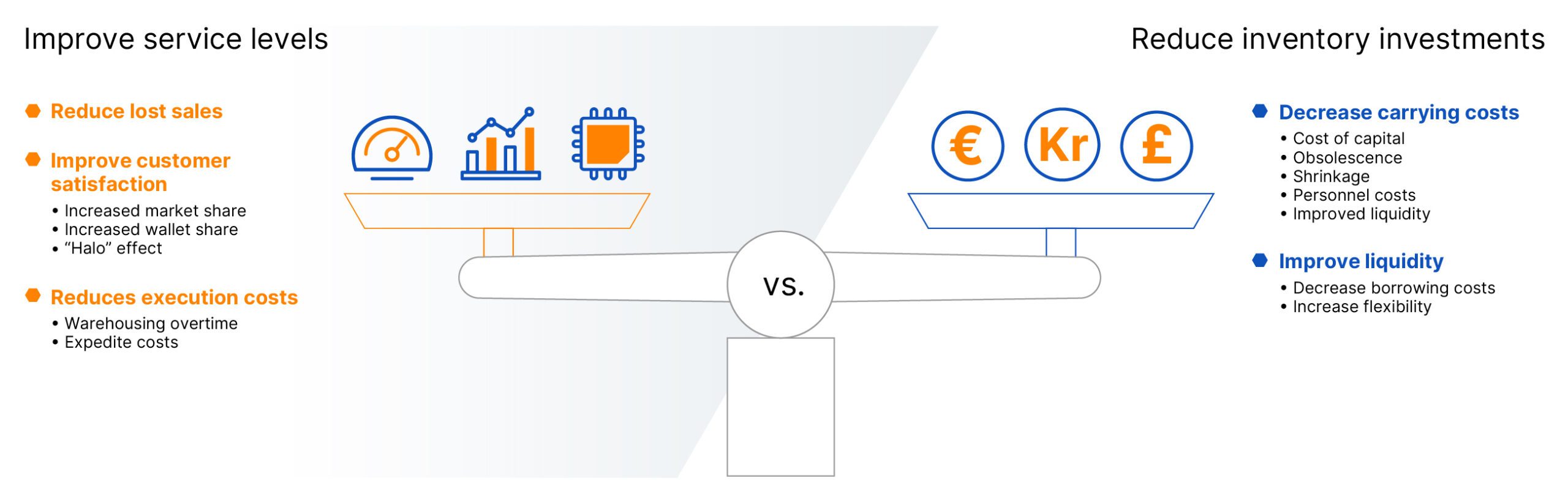

利益の成長を促進

シンクロンの Parts Planning だからできること:

- 現在のサービスを、より低い投資で提供

- 最小のコストでサービスレベルを向上

- 非生産的な資産の削減

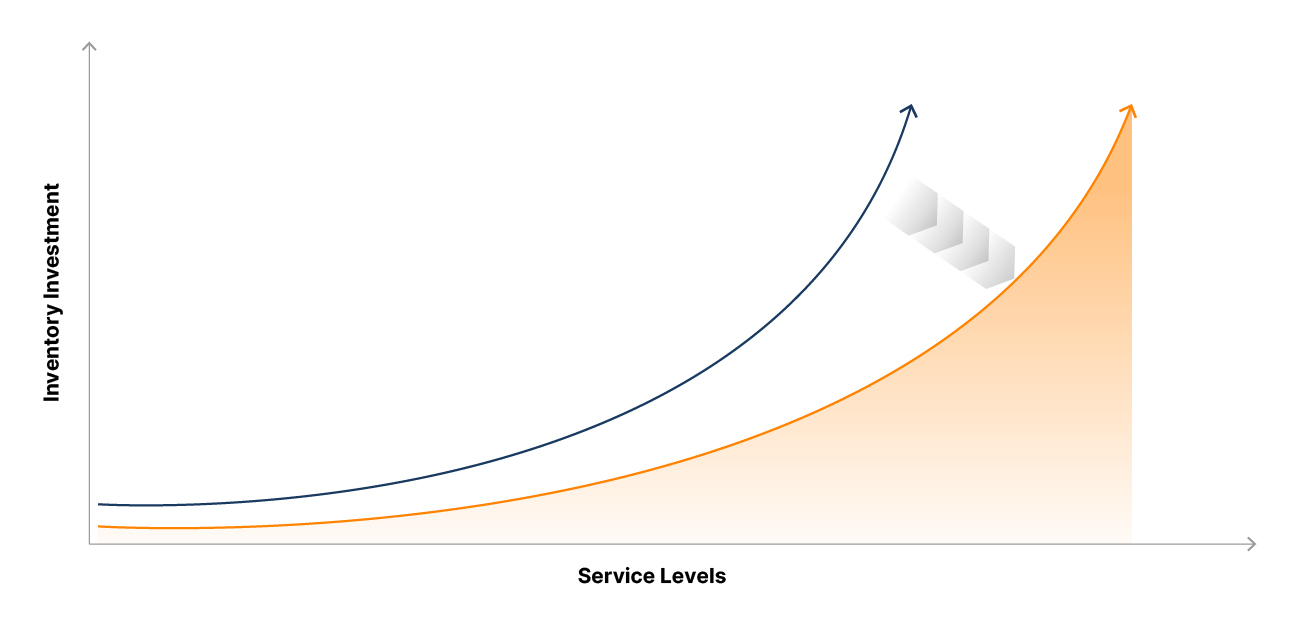

サービスレベルと投資の関係性

サービスレベルや部品供給の可能性が不安定な場合、サービスの維持に必要な在庫投資にも影響が生じます。

在庫投資を増減させることは、サービスレベルにも同様の影響を及ぼします。特にサービスレベルが極端に高い場合や低い場合に、その影響は大きくなります。

在庫保管コストの削減と流動性を向上

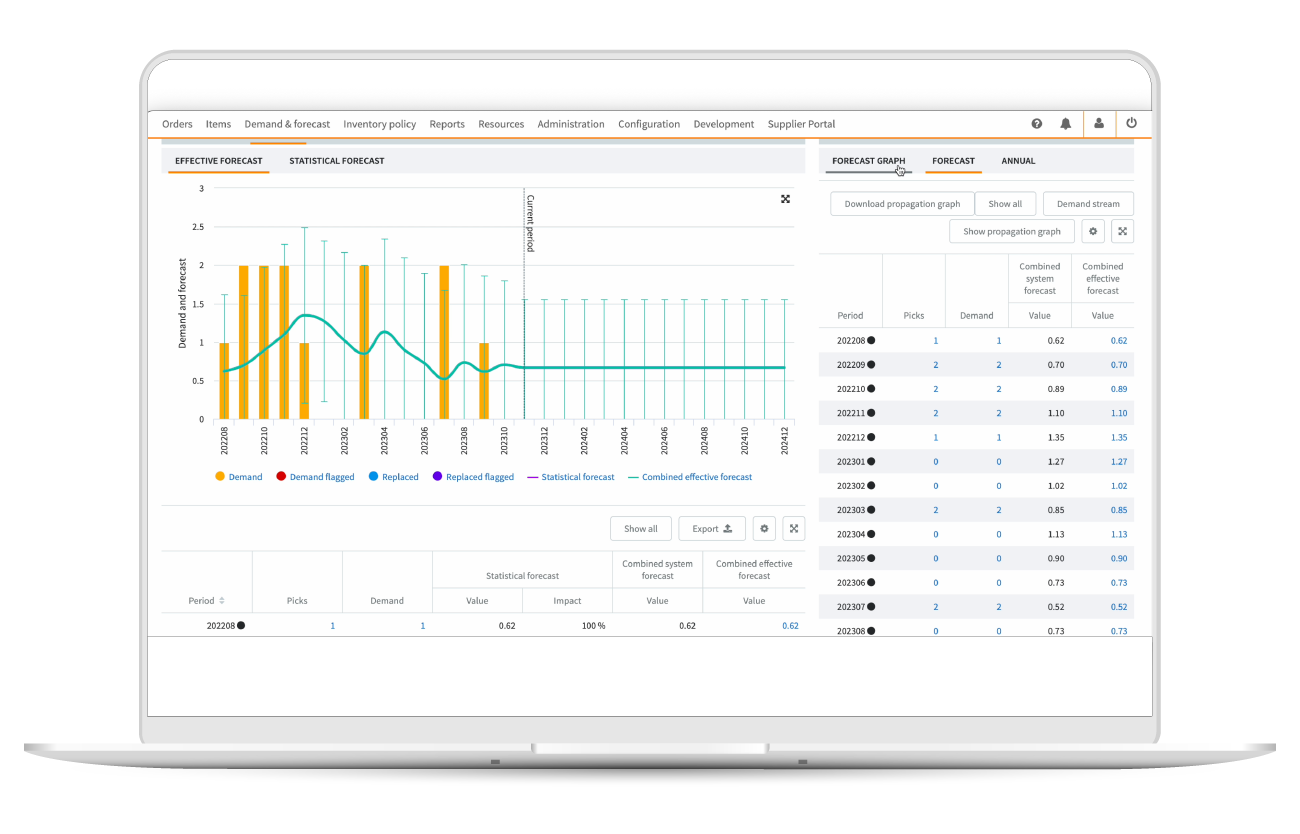

需要に基づいた統計予測

確率的AIモデルを活用し、数百万に及ぶサービス部品とロケーションの組み合わせにおける需要パターンを正確に予測。アイテムの動きに基づいて、9つの事前定義された需要タイプに動的分類します。

- 統計的インストールベースと因果予測

- サクセッションに完全対応

- BOMに基づき需要を集約

季節性と外れ値の検出

個別のアイテムまたはアイテム群における季節性を特定。季節性要因を自動的に特定し、計算。季節性があることがわかっているアイテムをクラスタリングして管理します。

- 外れ値となる期間や取引を特定

- 季節性要因の計算

- 季節性のあるアイテムをクラスタリング

サービスレベルと売上を向上

輸送コストと排出ガスの削減

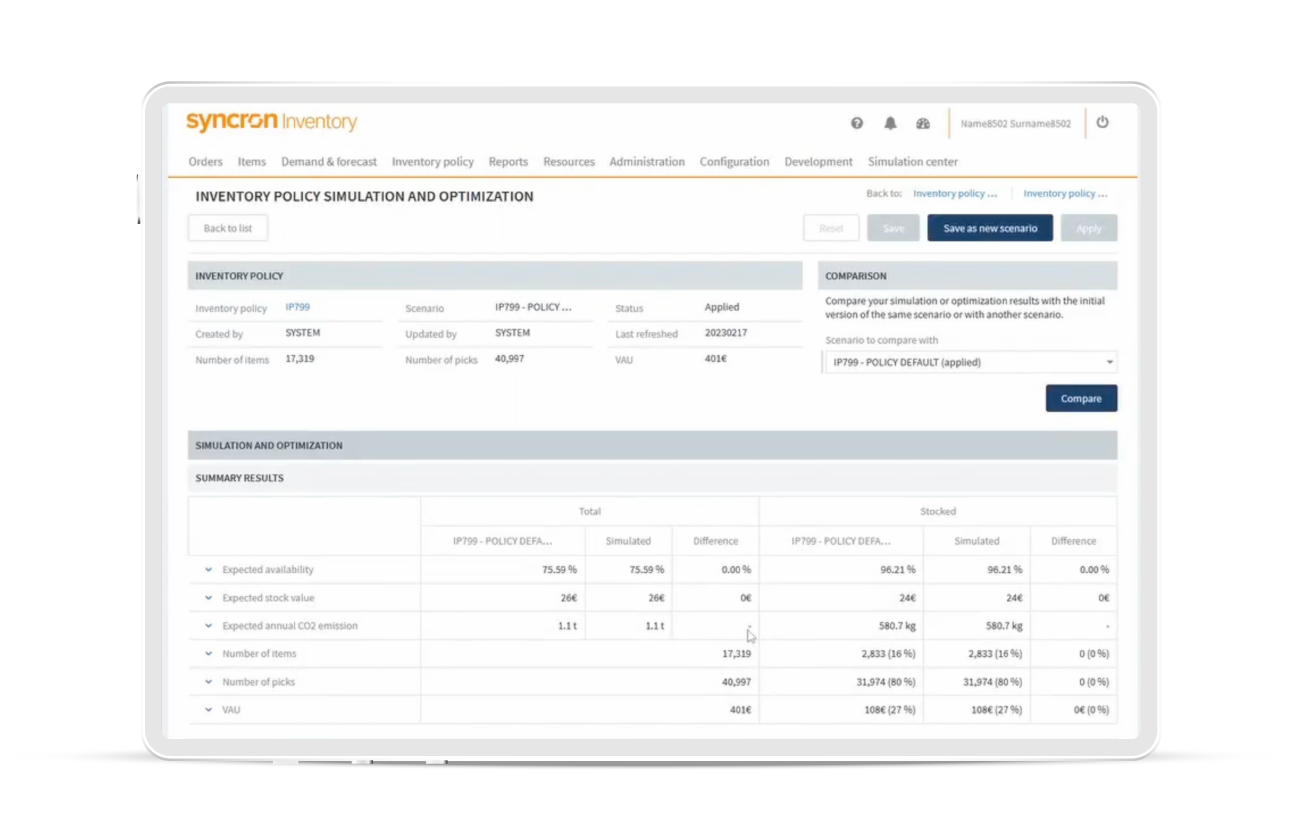

サービスレベルとコストの分析を、それぞれの物流手段による炭素排出量と連携。在庫保有、輸送、その他のアフターマーケットのサプライチェーンに関連するコストを最小限に抑えながら、サービスレベルの向上を実現します。

- アフターマーケットのサプライチェーンコストを削減

- CO2排出量の削減

- CO2排出量を大規模シミュレーション

再発注を自動化し

売上損失を回避

確立された在庫補充計画に基づき部品在庫を注文し、供給の可能性を最適化します。

- 注文の充足率を最大化

- 注文スケジュールと計画を共有

- 緊急注文を削減し、配送コストを低減

複雑なネットワーク向けに設計

実証済みの投資利益率(ROI)

部品供給の可能性やサービスレベルは、アフターセールスサービスにおける顧客満足度の判断基準となります。

シンクロンはIDC*の「世界的製造業のサービス部品管理アプリケーションリーダー」であり、アフターマーケットの専門家です。

*ITおよび通信分野に関する調査・分析、アドバイザリーサービス、イベントを提供するグローバル企業。

50+

大規模ビジネスのお客様企業数

40%

輸送費やその他のコストの削減率

20%

部品供給の可能性の向上率

20k

100か国以上での導入事例数

30%

部品在庫の削減率