シンクロンのDealer Parts Planning

部品供給の可能性を拡大し売上を最大化

IDC*認定の世界的な製造業サービスパーツ管理のアプリケーションリーダーであり、アフターマーケットのスペシャリストであるシンクロンによる、唯一の目的特化型AI搭載ディーラーパーツプランニングのソフトウェアです。

- ディーラーパーツ供給の可能性を向上し売上を拡大します。

- 返品や買い戻しの再補充を自動化して時間を節約します。

- 目的特化型ディーラーポータルで協力体制を強化します。

*ITおよび通信分野に関する調査・分析、アドバイザリーサービス、イベントを提供するグローバル企業。

シンクロンは世界中の大手グローバル企業に信頼される、サービスパーツ在庫計画のソリューションブランドです。

アフターマーケット向けの

設計で規模と複雑さに対応

シンクロンは製造業で拡大するディーラーネットワークをシンプルに管理できるよう支援。RIM(リテール・インベントリ・マネージメント)プログラムのマルチタスク処理で、大量なロケーションを単一管理することが可能です。

- デポレベルでのKPI報告

- コンプライアンスおよびインセンティブの管理

- インポートファイルの検証とアラート通知

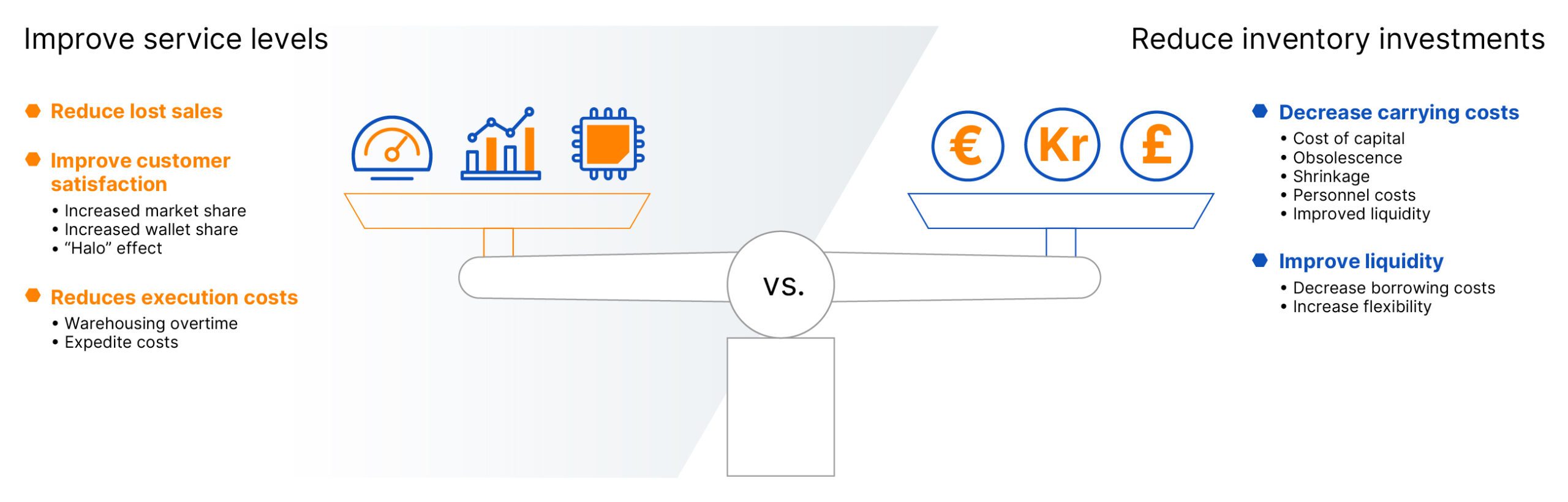

多角的なアプローチで

利益の成長促進

シンクロンのDealer Parts Planningは需要と供給や流通を予測し、所定の在庫投資額でより高いサービスレベルを実現。最適なコストでサービスレベルを向上させるための多角的なアプローチを採用しています。

- 流通を予測しパーツ計画を最適化

- コストの削減

- サービスレベルの向上

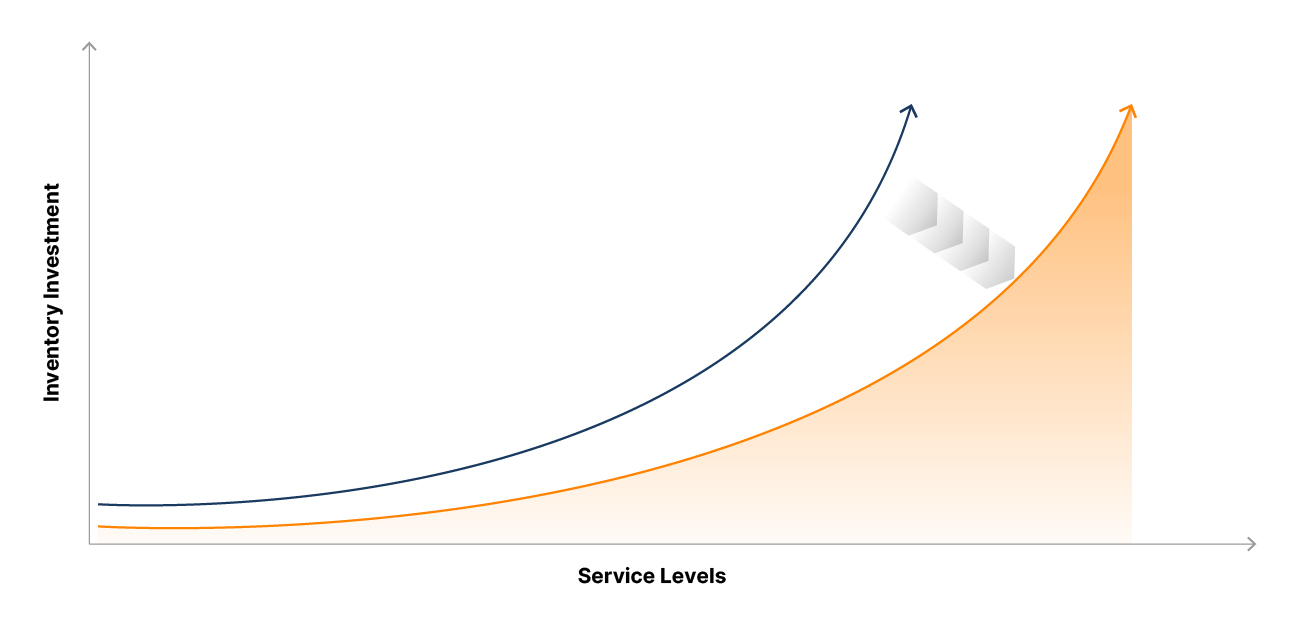

サービスレベルと投資の関係性

サービスレベルや部品供給の可能性が不安定な場合、サービスの維持に必要な在庫投資にも影響が生じます。

在庫投資を増減させることは、サービスレベルにも同様の影響を及ぼします —- 特にサービスレベルが極端に高い場合や低い場合に、その影響は大きくなります。

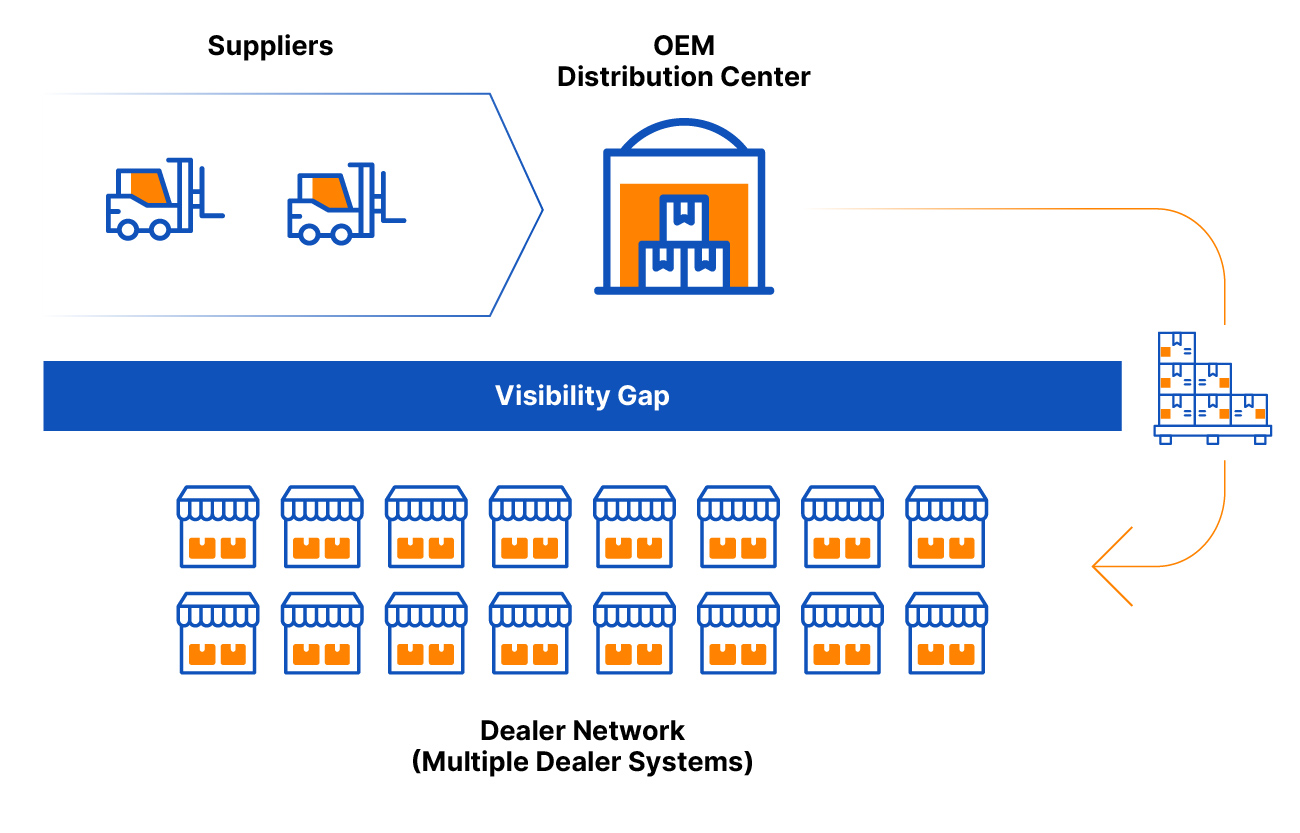

ディーラーサプライチェーンの同期化

部品を可視化し

ギャップを解消

データを活用して、ディーラーネットワーク全体のサービスサプライチェーンおよび在庫エコシステムにおけるビジネス機会を創出します。何百万という数があるディーラーのデータを統合し、明確で実行可能なインサイトを提供。「もしも」のシナリオ分析を活用して、ビジネスの成果を予測。GPSデータを活用して、現場の機器の位置を追跡します。

- 散在するディーラーのデータを統合

- シナリオ分析

- 機器の使用状況と位置を追跡

ウォレットシェア拡大に向け

ディーラーとの協力体制を強化

サービスレベルが向上することによって得られる最大の価値は、顧客と接する流通ポイントにあります。在庫管理戦略を自動化することで、最も効率的な数量でディーラーが部品を発注できるよう支援。クラスター分析で在庫管理を改善し、ディーラーの発注スケジュールや発注計画を部品配送センター(PDC)の計画と統合することができます。

- ディーラーへの部品発注を効率化

- クラスター分析

- ディーラーの発注スケジュールと計画を統合

「最優良企業は他の企業に比べ、ディーラーや流通業者を含むネットワークレベル全体で在庫を管理している割合が30パーセントも高い。」

運転資本の改善

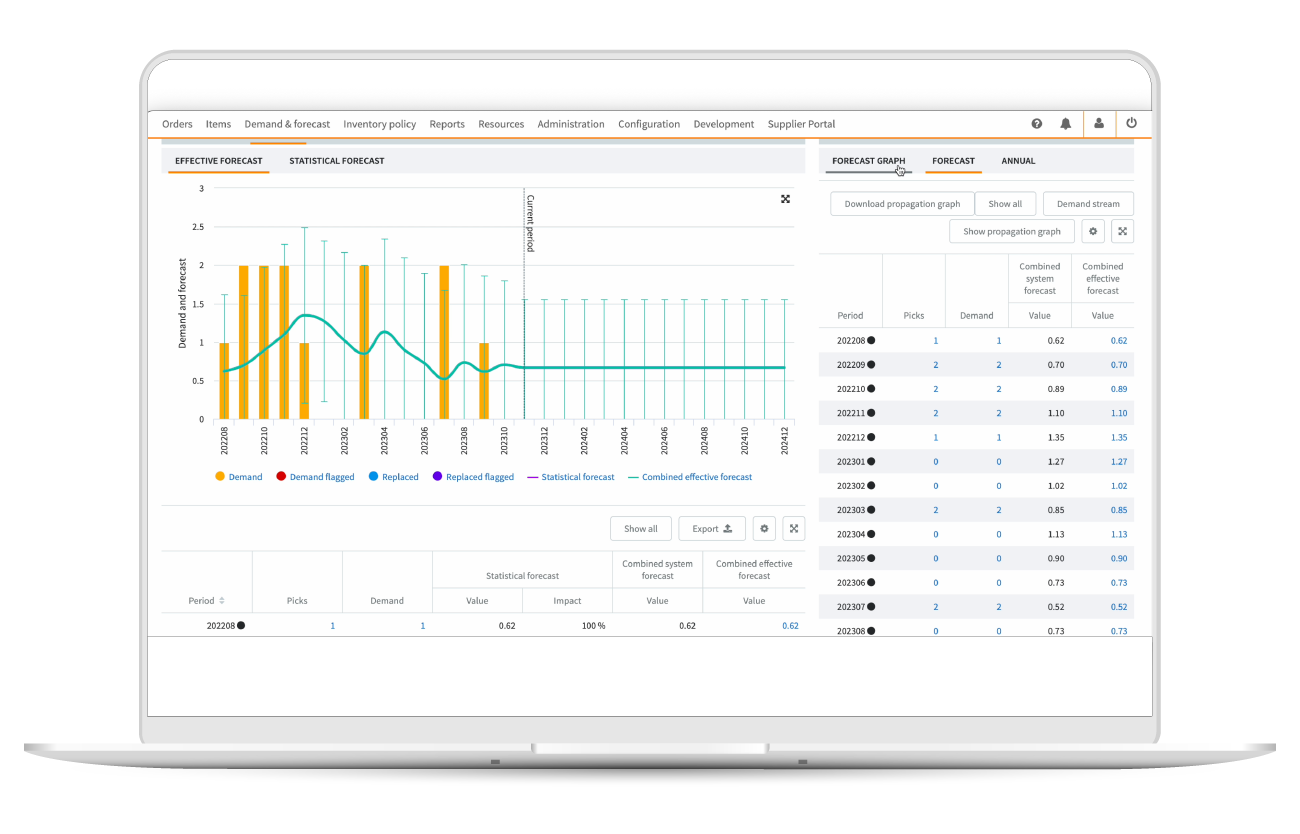

需要予測の精度向上

さまざまなデータセットを分析し、最適なアルゴリズムを適用。異なる需要の結果に対する確率を計算し、リコールキャンペーンやメンテナンスなどの予定イベントを調整・スケジュール。ハブアンドスポーク方式を活用し、部品を迅速に小規模ディーラーへも届けます。

- 需要の結果を計算

- 予定されたイベントをスケジュールし、調整

- 部品を迅速にディーラーに届ける

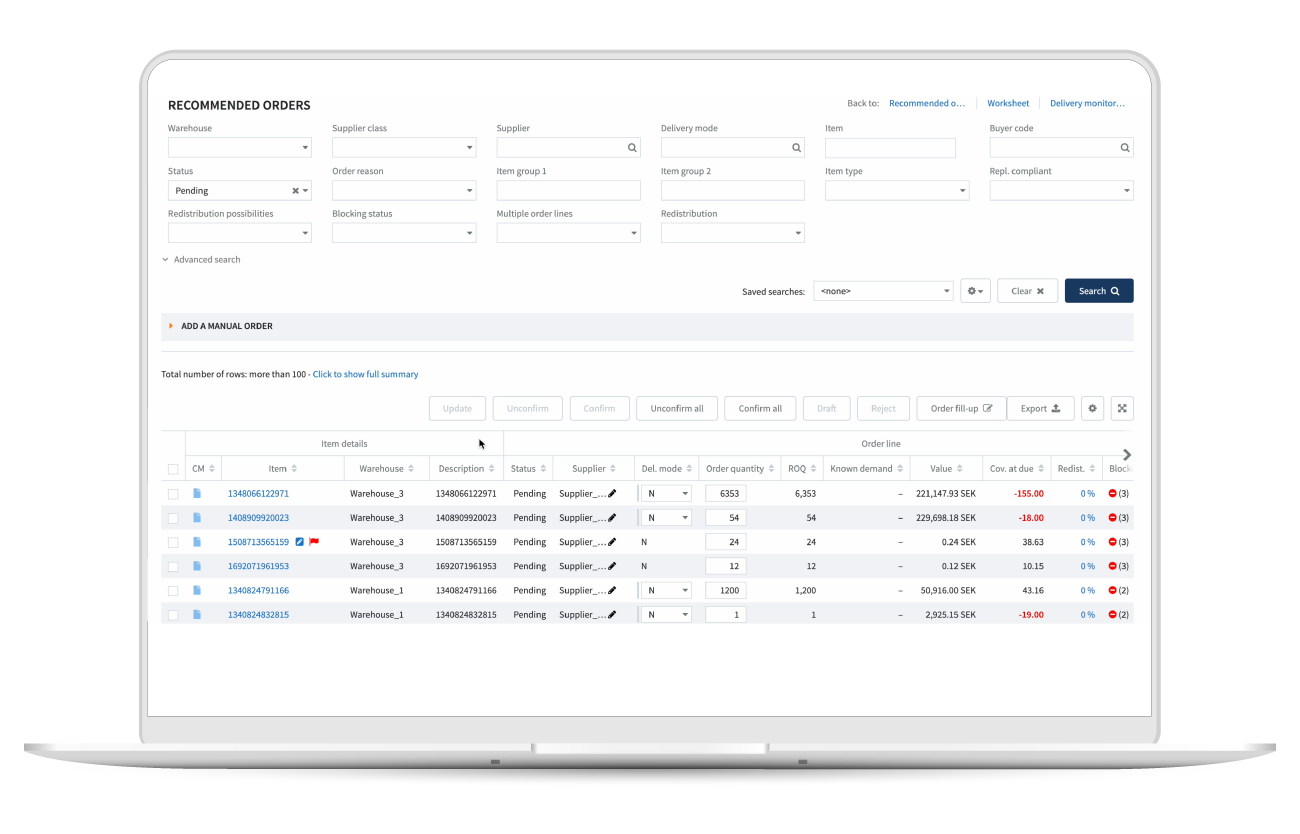

補充と返品を自動化

確立された在庫補充ポリシーをディーラーが実行できるよう支援します。ディーラーの在庫補充を自動化し、部品配送センター(PDC)でのサプライヤーの負荷を均等化。ディーラーの部品返品を簡素化します。

- 品切れのリスクを軽減

- 初回での修理完了率を向上

- 報酬や特典を活用し参加意欲とルールの遵守を促進

複雑なネットワーク向けに設計

実証済みの投資利益率(ROI)

部品供給の可能性やサービスレベルは、アフターセールスサービスにおける顧客満足度の判断基準となります。

シンクロンはIDC*の「世界的製造業のサービス部品管理アプリケーションリーダー」であり、アフターマーケットの専門家です。

*ITおよび通信分野に関する調査・分析、アドバイザリーサービス、イベントを提供するグローバル企業。

50+

大規模ビジネスのお客様企業数

40%

輸送費やその他のコストの削減率

20%

部品供給の可能性の向上率

20k

100か国以上での導入事例数

30%

部品在庫の削減率