Agriculture & Forestry Equipment Service Lifecycle Management Software

Maximize Equipment Uptime & Service Revenue

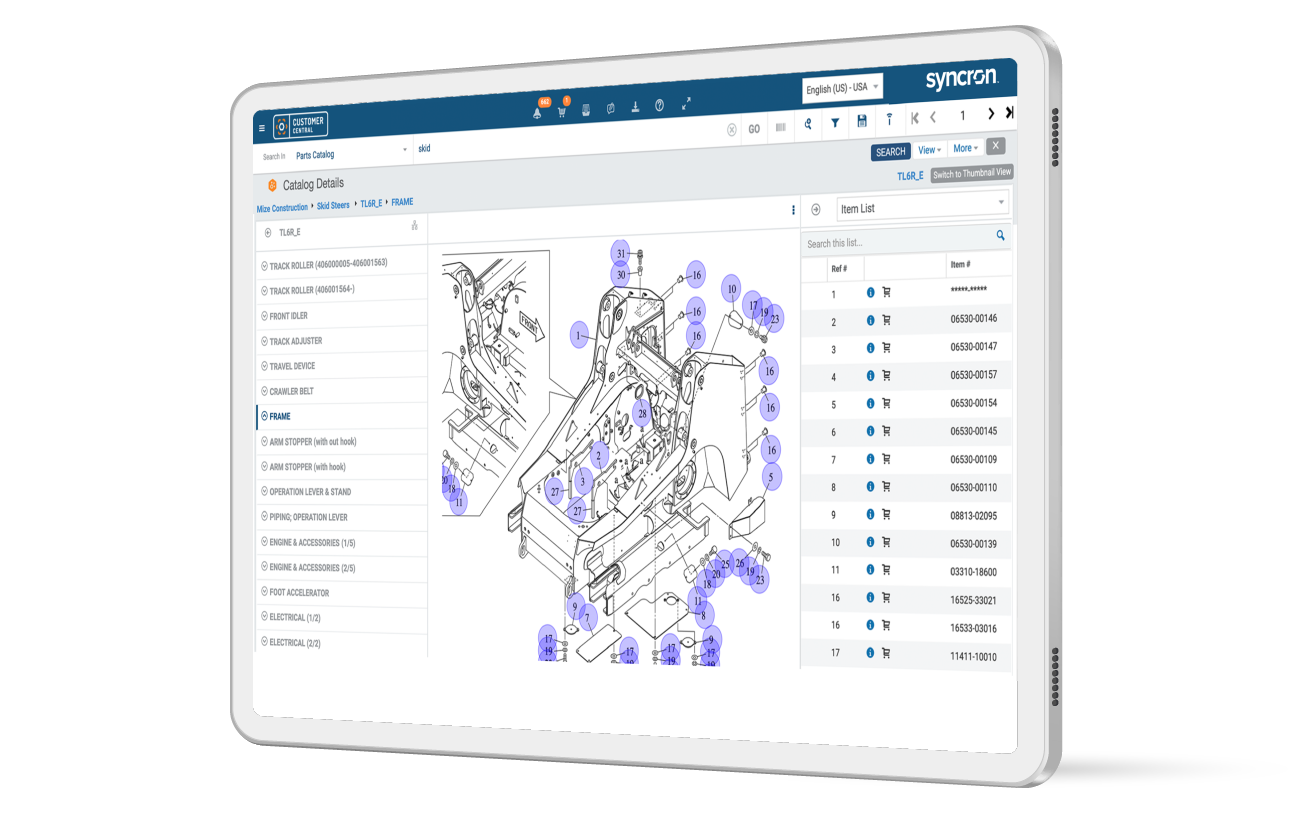

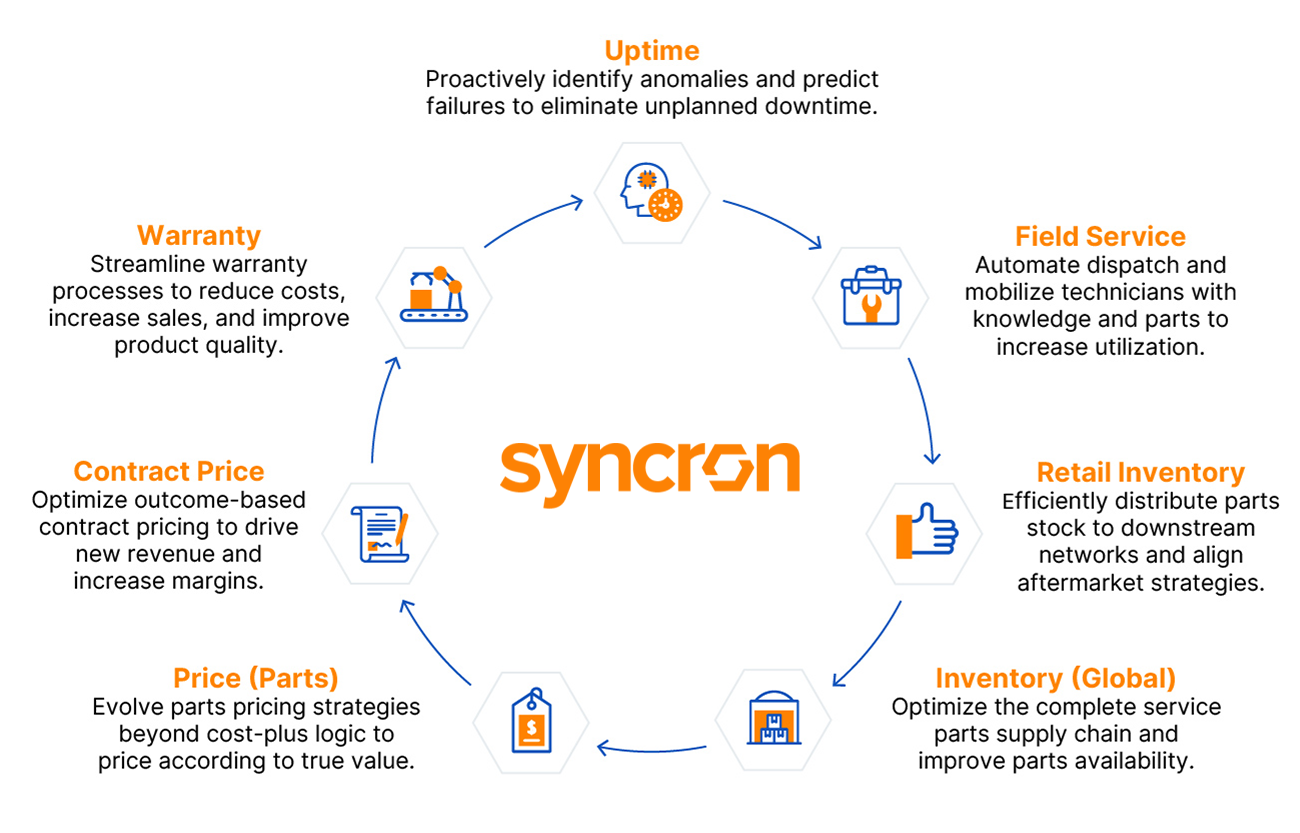

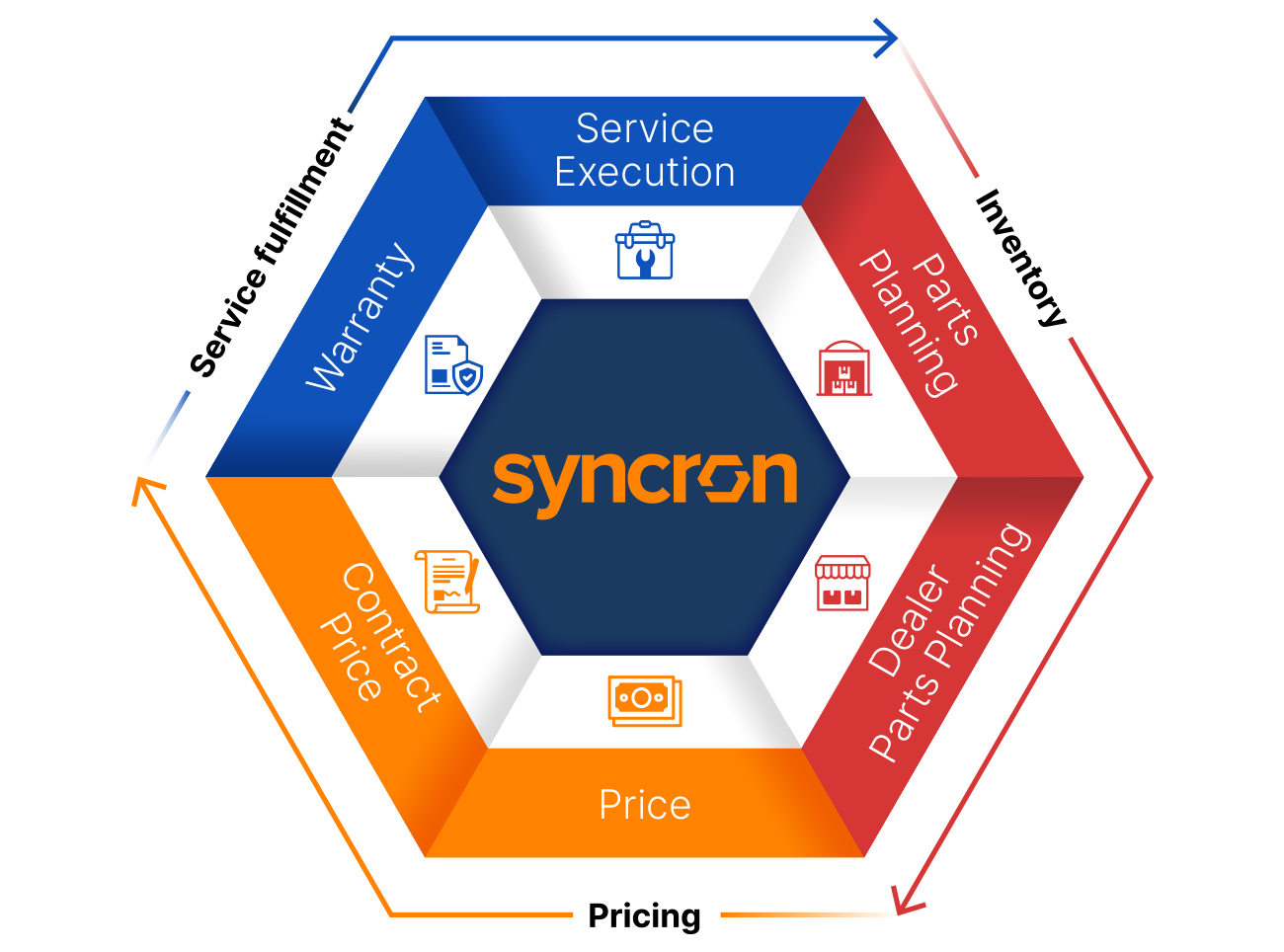

Integrate with dealers and 3rd Party Service Providers to offer farmers, foresters and contractors exceptional service – parts, pricing and maintenance for every machine every time from a single platform.

- Complete purpose-built AI-powered service lifecycle management (SLM) platform.

- IDC Worldwide Manufacturing Service Parts Management Applications Leader.

- Trusted by CLAAS, AGCO, Trimble, Kubota Tractor, MacDon, CNH Industrial and more.