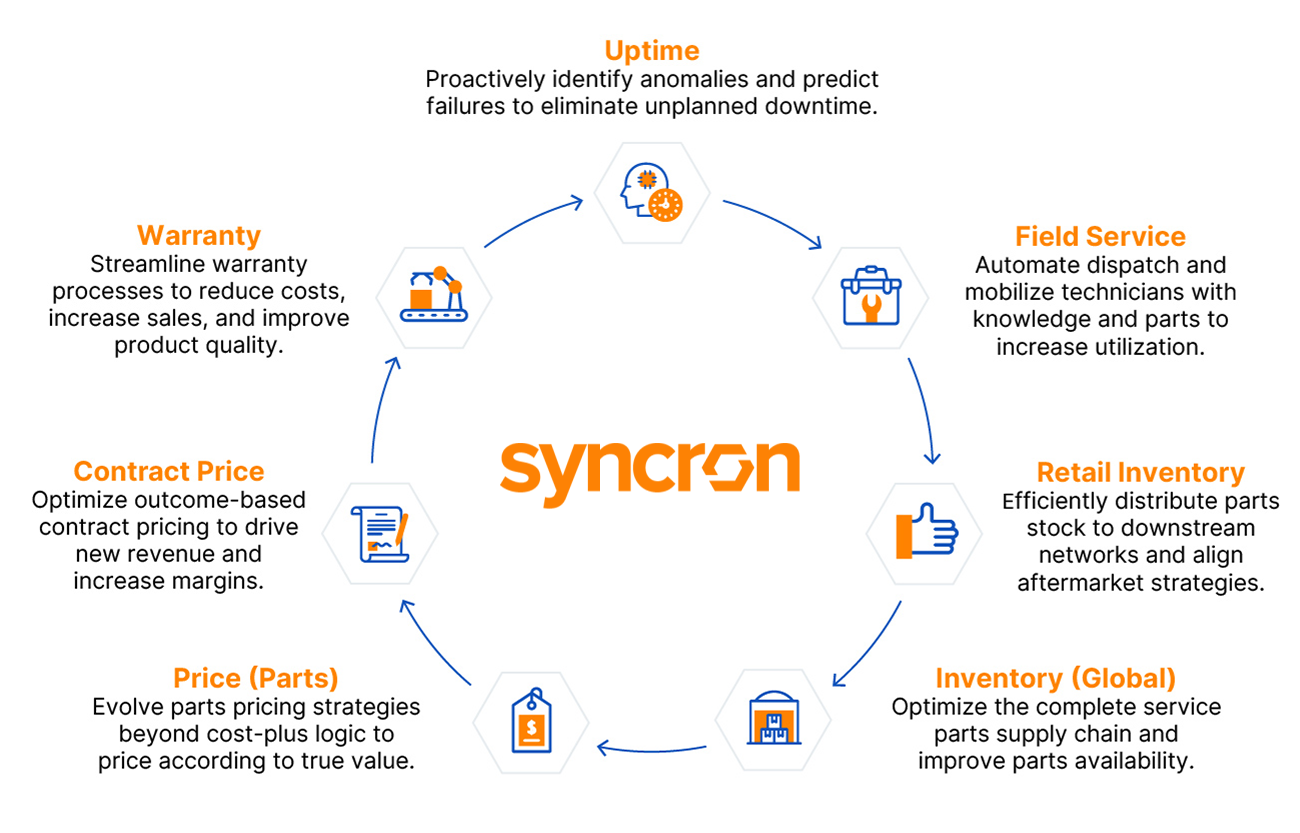

Automotive Aftermarket Service Lifecycle Management Software

Maximize Auto Parts Availability and Sales

Integrate the auto parts supply chain to offer commercial trucking and passenger vehicle fleet owners and consumer vehicle owners exceptional service – parts, pricing and maintenance for every vehicle every time from a single platform.

- Complete purpose-built AI-powered service lifecycle management (SLM) platform.

- IDC Worldwide Manufacturing Service Parts Management Applications Leader.

- Trusted by Volvo, Ford, Daimler Truck, Volkswagen, Nissan, Mazda, MAN Truck & Bus and more.